Hot Part Handling

Industry: Heavy Equipment and Rail

Application: Forging scrap

Material: Carbon steel

Products: Rings and Gear blanks

Situation

A forging facility in Wisconsin had problems handling red-hot parts during various processes. This scrap is hot and can be very heavy. Most traditional forge presses do not have a lot of space for large conveyors and use smaller, less rugged conveyors, for which durability in the demanding application can be challenge.

Solution

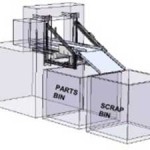

Shuffle conveyor designed specifically for this tough application.

Key Features

- The shuffle conveyor’s design allows for heavy repeated impacts without the need for much space.

- Matched the shuffle conveyors technology with a heavy-duty steel belt conveyor to elevate the scrap.

Customers Benefits

Small steel belt conveyors designed for this heavy application cost up to $10K each, and replacement conveyors were required every two years.

Outcome

The shuffle conveyors have been in place over five years with no appreciable wear.