Dry Cast Iron

Industry: Automotive Supplier

Application: Machining

Material: Cast Iron (Dry)

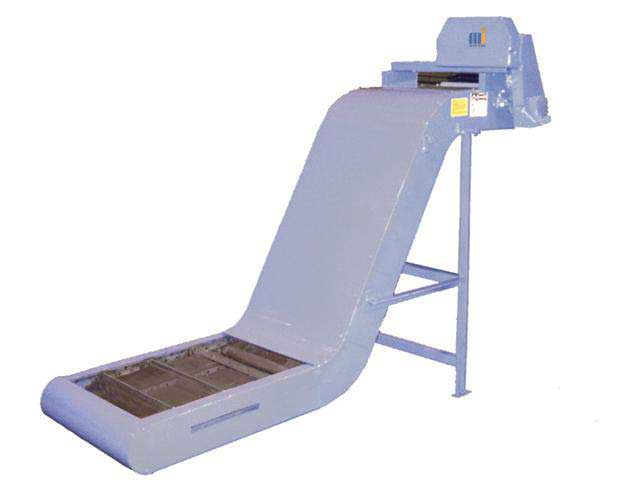

Product: Drag Conveyors

Situation

This customer was rearranging their plant to allow better flow of material. They had magnetic slider bed conveyors at each machine discharging into individual chip hoppers, but wanted to reduce the number of chip hoppers and amount of dust produced at discharge points and find a more reliable conveyor.

Solution

- Drag conveyors designed to provide a seal between the machine discharge and conveyor

- Multiple conveyors discharged into take-away conveyors that span that back side of the machining cell

Key Features

- Once in place, conveyors are sealed against the bottom of the machine by adjustable castors.

- All conveyor-to-conveyor transfer points are sealed to prevent dust migration

Customer Benefits

- Reduced number of chip hoppers by 60%

- Fork truck traffic to change chip hoppers reduced by 60%

- Dust problems reduced significantly