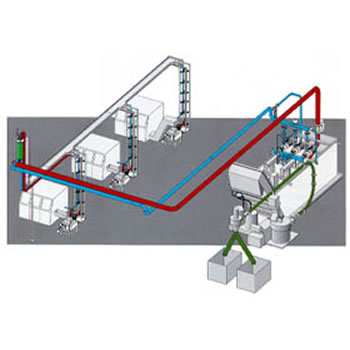

Central Chip & Coolant Collection Systems

We supply central chip and coolant collection systems for many applications. Some systems include conveying equipment that is installed under the plant floor. Other systems convey or pump the material overhead. These systems can include mechanical conveyors, pneumatic conveyors, or liquid pumping stations that are capable of pumping metal chips and coolant to a central filter. Let us know your requirements and we will offer the correct solution.

Case studies for this product:

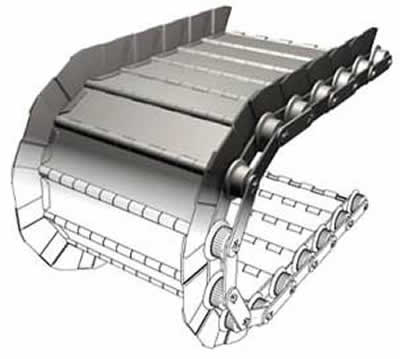

Central Scrap-Handling Systems

We have a long history of providing robust solutions for central scrap-handling systems to some of the largest stamping operations in the world, we specializes in providing turnkey scrap management systems based on hinged steel belt and shuffle conveyors. Incorporating several features designed to ensure high reliability and long life, our systems deliver outstanding automated scrap transport for years while keeping your operating costs low.

Case studies for this product:

Centrifugal Liquid-Particulate Separators

Our centrifugal liquid-particulate separators are designed to separate fine granular solids from aqueous or oil based fluids. They can be designed for a variety of applications and flow rates. The equipment can be portable or used as a part of a central system.

Chip Conveyors and Separators

Chip conveyors and separators are generally used with individual machine tools. They area used to remove the chips and fine material from the machining coolant. There are many factors that determine what type of this equipment is required. We supply a wide variety of solutions including not only the conveyor itself, but also any required tanks, pumps high-pressure coolants skids and secondary filtration equipment.

Case studies associated with this product:

Coolant and Process Fluids Coolers

We offer a complete line of coolant and process fluids coolers for use with oils and water-based fluids like machining coolants. Our coolers are used in machine tools for spindle cooling and coolant temperature control. They are also used in EDM equipment, medical equipment, lasers, and a variety of other processes.

Coolant Waste Minimization and Filtration

For wastewater containing oily emulsions or very fine suspended solids, our coolant waste minimization and filtration membrane systems have proven to be the most reliable treatment solution. These systems are easy to use and maintain, use less energy, and generate less airborne pollution than evaporators. Typical applications include filtration of spent coolants, emulsified coolant oil, and contaminated wastewater. These systems can reduce waste up to 98% without the use of chemicals.

Dust Collectors

Dust collectors have application in most industrial environments. Let us know your application and we will provide the right equipment to solve your problem.

Industrial Vacuums

We provide air and electrically powered industrial vacuums for wet and dry applications. These systems can be portable or used in a central location with multiple vacuum stations throughout your facility.

We will make sure that the correct equipment is applied for your applications. Metal chips can be a combustible hazard. Let us help you to apply safe and reliable equipment.

Magnetic Conveyors and Separators

Magnetic conveyors and separators come in a wide variety of designs. They are used to remove the chips and fine material from the machining coolant. They can be used with a single machine or as a central coolant separator. There are many factors that determine what type of equipment is required. We supply a wide variety of solutions including not only the conveyor itself, but also any required tanks, pumps, high-pressure coolant skids, and secondary filtration equipment.

Case study associated for this product:

Metal Chip Shredders

Metal chip shredders and crushers are often the first step in a chip handling and processing system to reduce the chip size to enable proper processing or transport, especially via overhead systems. Chip shredders also provide value as a potential stand-alone solution to reduce the volume and transportation costs associated with your scrap.

With over 13 models available, covering a range of sizes from machine tool level to central systems, we can provide a system that fits your specific needs. All models are auto-reversing to clear jams and include tramp part ejection.

Case study associated for this product:

Metal Chip Wringers

Metal chip wringers (or chip centrifuges) are used to dry metal chips or grinding sludge in order to recover valuable coolant, and increasing scrap value. They can generate a rapid payback on investment while simultaneously meeting ever more stringent environment regulations regarding chip disposal. Depending on the material and cutting fluid, dryness to less than 2% residual coolant can be achieved in your chip recovery operation. Our wringers are designed for heavy-duty continuous operation and include hardened components to reduce wear and prolong life. Our wringers can be used as part of a central processing system or at an individual machine tool.

Case studies for this product:

Metal-Cutting Coolant Filters

Metal-cutting coolant filters are generally used to remove solid particles from a continuous coolant stream. They can be used as a centralized system or at an individual machine tool. We use the term “filter” to describe equipment that uses some form of media (permanent or disposable) or barrier through which coolant is forced. Solid particles are trapped by the media and removed from the stream. There are many forms of this type of filter including gravity filters, vacuum filters, and pressure filters. We supply equipment in all of these categories. These projects are very application-driven. Let us know the problem that you are trying to solve and we can apply the correct equipment.

Case studies for this Product:

Mist Collectors

Metalworking companies use mist collectors on their machine tools to help provide clean air to reduce the adverse effects of exposure to metalworking fluids and comply with indoor air quality standards.

Portable and Central Metal-Cutting Coolant Recycling

Portable and central metal-cutting coolant recycling systems are simple but effective, and are used to remove tramp oil. They are designed to run continuously, removing tramp oil from machine tool coolants or other aqueous systems including quench tanks and wash systems. These systems are also available with a UV option for biological control.

Scrap Loadout Systems

With a range of options available, we can complete your scrap collection system with automated loadout into roll-off hoppers, balers, bins, or truck trailers. Scrap loadout systems include swivel chutes, diverter chutes, or shuttle conveyors, all of which can include laser sensors and automated feedback to provide level filling and communicate status automatically to central control systems. Direct notification to scrap haulers is also possible, truly minimizing your effort in managing your scrap system. Our systems are designed to the same exacting standards as our conveyors, enabling you to keep production running on even the most demanding schedules.

Our systems are designed to the same exacting standards as our conveyors, enabling you to keep production running on even the most demanding schedules.

Case studies for this product:

Stamping Scrap Removal at the Press

Our innovative Shuffle-Drive system leads the way in providing solutions for stamping scrap removal at the press, yielding improvements in press availability and throughput with reduced operating costs. With systems typically yielding a payback on your investment in less than a year, you can quickly enhance your competitiveness in the challenging metal forming market.

Case studies for this product: