Shuffle Conveyor Improves Pit Access

Industry: Appliance

Application: Stamping

Material: Steel

Product: Shuffle, drive conveyor, steel belt conveyor

Situation

An appliance manufacturer was looking for a new way handle their scrap due to the inaccessible nature of their scrap pits. The existing steel belt conveyors under the presses needed to be removed from the pits for maintenance. The narrow pits required undersized conveyors resulting in excessive scrap carryover and high housekeeping costs.

Solution

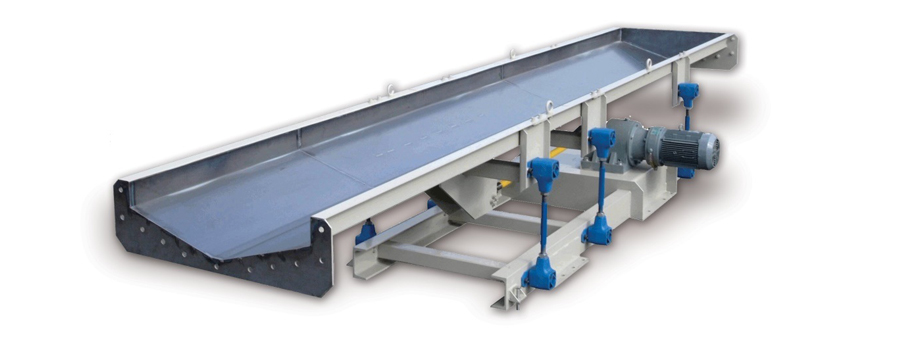

- Shuffle conveyor designed to run under the press to capture press scrap as it discharges.

- 2.5″ pitch hinged steel belt conveyor to elevate scrap out of the print and discharge into scrap hopper.

Key Features

- Shuffle conveyor is width of pit to maximize scrap capture

- Elevating conveyor was designed for easy removal from scrap pit if maintenance is required.

Customer Benefits

- Easy access to those needing preventative maintenance resulting in more reliable operation.

- The only required maintenance has been adding oil and tightening one tension arm.

Outcome

Customer has standardized on the shuffle conveyor for press scrap removal, purchasing 17 shuffle conveyors over the past few years.