Stamping Scrap and Part Handling

Industry: Automotive Supplier

Application: Stamping

Material: Carbon Steel

Product: Shuffle Drive(Press-Mounted)

Situation

Customer was removing parts and scrap from the end of die through the window of the press using an air operated shaker and tray system. Operation of the air shaker was noisy, inconsistent, unreliable and required constant maintenance and adjustment. After die changes, the system was time-consuming to reconfigure.

Solution

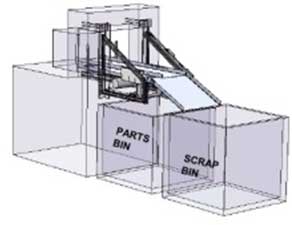

A custom-designed, two-tier tray system based on shuffle drive technology.

Key Features

- The two trays could be independently adjusted without tools to allow for different lengths and elevations of dies.

- The double-decker tray allowed the parts to run on the lower tray and drop into the parts bin while the scrap kept moving along on the top tray to the scrap bin.

Customer Benefits

- Quicker die changes

- Less press downtime – greater utilization

- Lower energy consumption and maintenance costs

Outcome

Performance exceeded customers expectations.